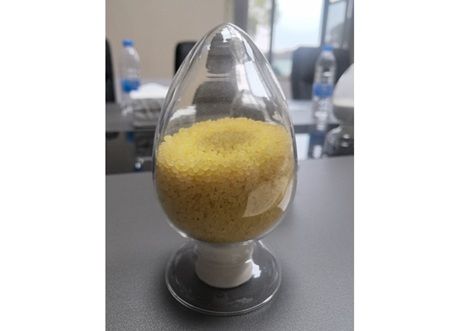

Product Introduction

The appearance of Go Green High Viscosity Asphalt Modifier (GHVAA) is a light yellow granular shape. It is a high-performance asphalt mixture modifier compounded from various polymers. It significantly improves the forming strength and stability of the asphalt mixture through multiple actions: tackiness enhancement, reinforcement, filling of the aggregate surface, asphalt modification, and elastic recovery. The product is easy to use and can be widely applied in fields such as drainage pavements and permeable pavements.

Product Mechanism of Action

1. Stabilizing Structure Effect

The high viscosity asphalt modifier softens under the effect of high temperature during the mixing process. It fully combines with asphalt and aggregate and fills and interlocks into the voids of the aggregate skeleton. This restricts the relative sliding between mineral particles and strengthens the interaction force between the mixtures, making the mixture structure more stable.

2. Reinforcing Effect

The micro-crystalline regions formed by the polymers in the high viscosity asphalt modifier possess considerable stiffness. During the mixing process, they are drawn into fibers. The fibers interlace and intertwine, forming a three-dimensional mesh structure that firmly restricts the mineral particles within the mesh, thereby greatly improving the overall strength of the asphalt mixture.

3. Deformation and Recovery Effect

When the high viscosity asphalt modifier is added to the asphalt mixture mixing equipment at high temperatures, the additive is in a viscous flow state. Through wetting and infiltration, the modifier uniformly coats the surface of the mineral particles. When the temperature cools, the interface where the mineral particles are cemented is in an elastic state, which has high stiffness and strength.

Production and Construction Process

Mixture Production

1. Dry Mixing Process

The direct addition method is used: the high viscosity asphalt modifier (with an addition ratio of 6‰-8‰ of the aggregate) is added together with the dried aggregate into the mixing drum of the asphalt mixing plant for dry mixing. After 10S of dry mixing, the base asphalt and mineral powder are added and mixed for about 40S.

2. Wet Mixing Process

The high viscosity asphalt modifier is directly added to an asphalt storage tank with stirring, according to the proportion (the mass ratio of modifier to asphalt is 10~14:90~86. The mixture is continuously stirred for 2-4 hours while maintaining a temperature of 180℃-190℃. Once uniformly mixed, it becomes the finished high viscosity asphalt. For use, the high viscosity asphalt is heated to 170℃-175℃ and then directly pumped into the asphalt mixture mixing plant for mixture production.

Notes: When producing with either process, the aggregate should be dried to 190℃-200℃. Mixing should be uniform, all mineral particles should be coated with high viscosity asphalt, and there should be no segregation, no white spots, no clumping, or severe segregation. The discharge temperature should be controlled at 180℃-190℃.

3. Mixture Storage and Transportation

Open-graded high viscosity asphalt mixtures have less fine aggregate, dissipate heat quickly, and the asphalt viscosity is high. Therefore, prolonged storage and transportation should be avoided.

4. Paving and Compaction

Paving and compaction are carried out according to the normal construction. Since the viscosity of the high viscosity modified asphalt mixture rapidly increases as the temperature decreases, compaction and forming should be completed soon while the mixture temperature is still high during construction.

Below is the technical data for high viscosity asphalt additive:

Product Technical Specification

Inspection Item | Unit | Technical Requirement | Test Result | Judgment |

Appearance | / | Granular, uniform size | Granular, uniform size, no clumping | Standard |

Color | / | Yellow | Yellow | Standard |

Mass of Single Particle | g | ≤0.5 | 0.013 | Standard |

Diameter | mm | ≤3 | 2.4 | Standard |

Density | g/cm³ | ≤1.0 | 0.958 | Standard |

Melt Mass-Flow Rate (190℃/2.16kg) | g/10min | ≥10 | 14.7 | Standard |

Ash Content | % | ≤1.0 | 0.108 | Standard |

SBS Content | % | ≥60 | 62 | Standard |

Go Green high viscosity asphalt additive can be widely applied on:

Application Range

Permeable pavements and drainage pavements.

Heavy traffic asphalt pavements.

"White-to-Black" projects (conversion of cement pavement to asphalt pavement).

High-grade pavements such as highways and airport runways.

Package

5kg/25kg bag.

Should be sealed and stored in a cool, dry place.

The storage period is 2 years.