Go Green PU ColdMix Color Binder is an innovative cold-applied colored pavement material based on high performance polyurethane resin. The binder is pre-mixed with weather resistant pigments and multiple functional additives. During construction, simply blend with aggregates on site according to the recommended ratio — no heating equipment is required. The mixture can be directly paved and compacted at ambient temperature. It is particularly suitable for light-traffic pavements and provides a green, efficient solution for colored surfaces.

Key Advantages:

Cold mix application, no heating required

Fully cold-applied with no need for burners or heating devices. The process is smokeless and odorless, more environmentally friendly, and greatly reduces construction difficulty and on-site safety risks.

Fast installation and easy to use

The binder is pre-formulated, so the entire process only requires "add aggregate – mix – pave". Ideal for rapid construction, emergency works, or small-section applications.

Significant savings in production and transportation costs

No heating equipment → reduces equipment investment and energy consumption

On-site cold mixing → no thermal trucks needed; simpler logistics

Concentrated liquid binder → lower transportation volume and reduced storage pressure

Long lasting color and excellent decorative performance

Formulated with high-durability pigments, offering bright and stable colors that resist fading. Ideal for landscape and municipal decorative pavements.

High bonding strength and long service life

The polyurethane binder provides excellent adhesion, weather resistance, and abrasion resistance, ensuring long-term pavement stability.

Ideal for light traffic applications

Suitable for park pathways, pedestrian walkways, bicycle lanes, scenic routes, residential areas, school campuses, and other lightly loaded pavements.

Construction Process:

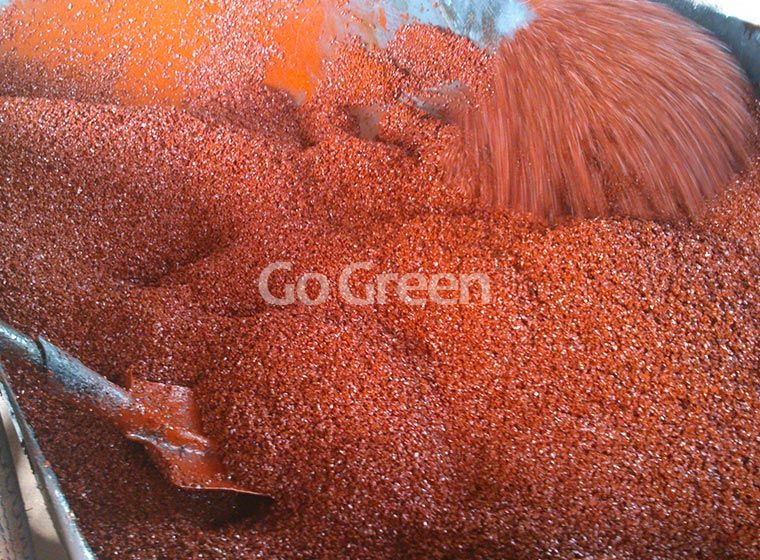

Add dry and clean aggregates according to the recommended ratio: Standard binder-to-aggregate ratio: 1:18 (for very clean aggregates), if aggregates contain dust use 1:16.

Mix Component A and Component B at a 4:1 ratio, then add the blended binder in several portions into the mixer (concrete mixer recommended).

After binder and aggregates are fully mixed (typically 5–7 minutes), proceed with paving. Optimal workability within 10 minutes; Do not exceed 30 minutes.

Spread and level the mixture. Recommended layer thickness is 4–5 cm in one pass. For thicker layers, pave and compact in multiple layers.

Compact and allow curing for 8–12 hours before pedestrian access. Full curing takes 72 hours—vehicles must not enter before full cure.

Application Notes:

For cement concrete substrates, a primer is required. As the primer is classified as hazardous, and we cannot ship it directly. Therefore, it is recommended to purchase polyurethane primer locally (transparent PU primer). If polyurethane primer is unavailable, applying a thin layer of the A+B binder mixture can serve as a substitute primer.

Cement surfaces must be ground and cleaned thoroughly before application.

The PU ColdMix Color Binder is suitable for park pathways, pedestrian walkways, bicycle lanes, scenic routes, residential areas, school campuses, and other lightly loaded pavements.

Package:

Component A (colored binder) + Component B (brown hardener)

Total: 25 kg/set (20 kg Component A + 5 kg Component B)

Storage:

Shelf life: 12 months